Global Navigation

Main Navigation

Left Navigation

- Products

- UV lamps

- IR lamps

- Quartz glass

- Reflectors

- Coatings

- Electrics

- Cooling

- Cooling water

- Ventilation/Mechanics

Content

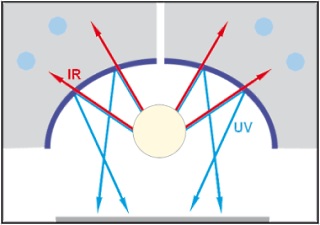

Coatings

Heat, ink, dust, powder and incorrect cleaning methods are just some of the factors that can impair the performance of reflectors. As a consequence, they become dull, and the degree of reflection is diminished substantially. Thus, the reflectors are not damaged mechanically.

Reflector soiling and the consequences:

|

|

With our newly developed Highlight UV-Products  process, we can apply a fresh coating on soiled and burnt aluminium reflectors. According to the required application field, our customers can choose between three different coating types.

process, we can apply a fresh coating on soiled and burnt aluminium reflectors. According to the required application field, our customers can choose between three different coating types.

Advantages for Highlight UV-Products customers:

|

|

Footer

Copyright © 2024 Highlight UV-Products GmbH & Co. KG

Copyright © 2024 Highlight UV-Products GmbH & Co. KG